If you are checking this article, you are wondering about the chemical PPE.

What are they?

Why do we need them?

How to choose the right ones?

Fear not… here, you will discover the answers to all your chemical PPE questions.

Hazardous chemicals can be found in several work environments. And we will make sure you are safely protected when you use them.

Therefore, this article will tell you about PPE, chemical PPE, and why we need them. We will also examine different types of chemical PPE and explain their uses.

Additionally, you will know more about their features and the different level of protection they offer. Then we will offer tips for choosing the right PPE and knowing how to handle chemicals safely.

Finally, we will mention other hazards you might need to combat.

Let’s start with what chemical PPE is.

Chemical Personal Protective Equipment (PPE) is used to combat chemical hazards. However, chemical PPE doesn’t substitute for safety protocols and procedures.

Thus, an institution where the staff has to handle hazardous chemicals must have a standard procedure for work. Additionally, they should provide every staff member with the required protective gear.

What kind of hazards are we talking about?

When working in a lab, hospital factory, or plantation, you are exposed to chemicals. Some of these chemicals are considered a hazard to humans due to their effect on our health.

Chemical hazards

Laboratory personnel, for example, handles chemicals all the time. Chemicals are divided into acids, alkalis, and solvents.

These chemicals are available in different forms. For instance, they could be:

- Liquids

- Solids

- Gases

- Vapors or fumes

- Mists

- Fibers or dust

Chemicals can cause permanent damage to humans.

The damages can be chemical burns, allergies, asphyxiation, and cancers, depending on the used chemical. Additionally. hazardous chemicals can cause genetic mutations and deformations in fetuses.

Thus, all chemicals are labeled to help workers handle them in a safe manner. Workers, lab assistants, and other staff must wear chemical PPE when handling hazardous chemicals.

Bottomline

Hazardous chemicals can be fatal if not dealt with properly. They can cause long and short-term effects on one’s health. Additionally, hazardous chemicals can be found in several forms.

Therefore, using chemical PPE is standard in work environments that use chemicals.

What is PPE?

Personal protective equipment is a broad term that encompasses any safety instrument or clothing workers use for protection.

PPE includes chemical-resistant gloves, safety vests worn at construction sites, and everything that falls in between.

Why do we need PPE?

PPE is designed to protect workers from serious injuries resulting from exposure to hazardous matters. These hazards could be chemical, radiological, physical, electrical, or mechanical.

However, not a single set of PPEs can protect its own. PPE is used in conjunction with protective procedures.

Additionally, different PPEs are used to protect:

- The respiratory system

- Eyes

- Ears

- Skin

Therefore, PPE includes:

Hard hats: There are different types of hard hats. Choosing the right one for your profession depends on the hazards you face. Hard hats are tested to assure they fulfill the requirements of head safety.

Safety glasses (goggles): The eyes are sensitive organs. Chemicals, flames, or even hot vapors can cause permanent damage to one’s eyes.

Therefore, welders, chemical manufacturers, or lab assistants must wear protective goggles.

Ear plugs: In some work facilities,, the noise level is higher than the limits set by the Occupational Safety and Health Administration (OSHA). Thus, there are standards for hearing protective gear that must be met to protect workers.

Body protection: This is a broad category. Body protection is governed by several different standards. However, this broad category includes aprons, gloves, safety vests, HAZMAT suits, and much more.

Boots (or shoe covers): According to OSHA, protective footwear in hazardous environments must follow two standards. These standards are established by the American Society of Testing and Materials International (ASTM).

Bottomline

PPE is a method of protecting oneself from any sort of hazard. They are not just the garments you wear the tools you use and the procedure you follow.

Therefore, PPE is usually used to protect one’s head, eyes, ears, and body. This requires hard hats, googles, ear plugs, body protection, and even boots.

Let’s take a look at the chemical PPE

Chemical PPE is manufactured to offer protection to the whole body. Additionally, respirators and masks are used to shield the respiratory system.

Thus, PPE aims to protect the respiratory system, hands, eyes and face, feet, and body.

So, let’s examine chemical PPE closely.

-

Respiratory system protection

Atmospheric hazards like fumes, vapors, particles, and gases have a detrimental effect on the respiratory system. Fumes, for example, usually contain vapors and dust. While vapors are mostly corrosive or toxic.

Hydrochloric acid droplets were found to cause chemical burns within the respiratory tract. Therefore, fumes are more dangerous than other atmospheric hazards.

Hence, it’s crucial to reduce the emission of fumes. Incorporating fume hoods in the facilities’ infrastructure will achieve that.

Additionally, respirators should be used by individuals working with fume-emitting chemicals.

-

Respirators

If your facility doesn’t have a fume hood, you must wear a respirator. Respirators either remove the contaminants from the air you are breathing, or they are attached to an oxygen tank.

Initially respirators covered your mouth and nose. Yet, some brands cover the eye and face as well.

There are two types of respirators available:

Air Purifying Respirators (APR): this type prevents the hazards in the air from entering your respirator and your lungs using filters. This means the air is filtered first. Thus, guaranteeing that nothing but clean air is inhaled.

Supplied Air Respirators (SAR): this type prevents contaminated air from entering. While the breathed air comes from a tank that you can easily wear on your back.

Precautions for using respirators

While it seems that respirators solve all breathing problems, there are some cases where they might fail. Individuals suffering from heart and lung problems can’t wear respirators. As this PPE requires your heart and long to work harder than usual.

Therefore, if you suffer from a heart and lung condition, our advice would be to avoid environments filled with atmospheric hazards.

Additionally, for a respirator to work correctly, facial hair must be removed.

How to fit a respirator?

If your respirator doesn’t fit you, you are still at risk of inhaling hazardous chemicals. Therefore, every time you wear your respirator,, you must perform a seal check to ensure fitness.

The sealing check takes place by blocking your hands’ air inhalation and exhalation ports. Then, breathe in and out deeply. If you detect any air coming in from the sides, your respirator doesn’t work correctly.

Bottomline

Protecting your respiratory system from hazardous fumes and gases is not to be taken lightly.

If applicable, fume hoods should be installed in labs where fume emission occurs. If not, then respirators are the perfect PPE to be used in these environments where the emission of fumes is inevitable.

-

Hand protection

Gloves can be used in labs, clean rooms, hospitals, and many other places. They are another essential part of chemical PPE.

Latex or nitrile can be practical when handling mild chemicals or biological samples. Yet, when dealing with acids or solvents, you need something much more substantial. You need chemical-resistant gloves.

Thus, if you work in such conditions, you can use either acid or solvent gloves.

-

Acid gloves

This type of glove offers more protection against corrosive acids. One can wear them on top of any regular disposable gloves. Additionally, more than one acid glove can be worn simultaneously.

Thus, these gloves are made from materials that can endure acids. For example, you can find:

- Nitrile rubber acid gloves

- Butyl rubber acid gloves

- Natural rubber acid gloves

-

Solvent gloves

This type of glove is inert. They are used to handle chemical cleaners and solvents. Therefore, one must wear a pair of regular disposable gloves underneath them.

You might think that they are precisely similar to acid gloves. However, solvent gloves are manufactured using thick nitrile.

Donning and doffing acid and solvent gloves

These gloves come with a two-inch cuff to ensure that acid doesn’t run up your arm. Therefore, when donning more than one glove, the outer one only needs to have a two-inch cuff.

When doffing the gloves, you should pull the cuff while turning the glove inside out. Then, you should dispose of them in a designated area.

Leak test

It is crucial for these types of gloves to be hole-free and puncture-free. Therefore, a leak test must be done before donning the glove. This test can take place using one of two methods.

- You can blow air inside the glove-like you do with a balloon. Then, you listen for air coming out of any hole.

- You can fill the balloon with nitrogen and submerge it in water. If you see bubbles, then the gloves are damaged.

In both cases, the gloves should be disposed of. And the tests should be repeated with a new pair.

Bottomline

Gloves are essential in work environments where workers use acids and solvents. These chemicals can lead to severe damage to the hands. Therefore, thick gloves are a must-wear.

Thus, there are two types of gloves that can be used in such environments; acid and solvent gloves. Additionally, you can use the same donning and doffing techniques for both types of gloves.

Leak tests are of the most important to ensure your gloves one leak chemicals that will harm you.

-

Face and eye protection

Our face is the first thing anyone looks at when they meet us for the first time. Thus, protecting your face and your eyesight is no joke whatsoever.

That being said, there are two chemicals PPE used to protect one’s face and eyes.

-

Face shield

A special face shield is designed to protect you from acids and solvents. Therefore, the shield must be on the entire time you work with chemicals.

Additionally, the face shield is worn over the lab goggles to ensure maximum eye protection.

-

Eye goggles or safety glasses

This safety instrument is essential in cleanrooms and chemistry labs. Additionally, they all must have side shields to optimize their role.

Eye goggles can be worn over your glasses. Also, they can be manufactured using prescription lenses for those who work with hazardous chemicals most of the day.

Bottomline

Face shields and eye googles are a part of the chemical PPE. Face shields are worn over eye googles to maximize eye safety.

-

Foot protection

You need to protect your feet from chemical spills. Therefore, we recommend chemical-resistant boots. Yet, these boots don’t offer absolute protection.

So, regular high-heeled shoes should be worn underneath them.

-

Chemical resistant boots

The boots offer more protection when dealing with acids and solvents. They are usually made of vinyl and are used in cleaning chemicals.

Bottomline

Vinyl chemical-resistant boots are worn over regular high-heeled shoes for extra protection.

-

Body protection

Protecting your body from chemical splashes requires using an apron or a chemical-resistant suit.

-

Aprons

They are made from rubber-based material. However, for them to provide the best protection, they need to cover the entire length of the body.

Additionally, aprons are easier to take off in case of acid or solvent splashes. This gives them some advantage over chemical-resistant suits.

-

Chemical resistant suits

Chemical-resistant suits are usually made from rubber or neoprene. They provide the highest level of protection when you are cleaning chemical spills. HAZMAT suits are the safest type of protective suits.

Therefore, this PPE is used in a variety of fields.

Bottomline

Our bodies need to be protected from chemical spills. Thus, using aprons or chemical-resistant suits is a must. However, the suits provide higher levels of safety and protection.

What are the most common features of chemical PPE?

There are two standard features that should be checked when considering chemical PPE.

- Permeation rate

- Degradation

Permeation rate

It is the rate by which a hazardous chemical can move through the intact material of your PPE and reach your skin. This is measured using breakthrough time.

However, permeation is different from penetration due to cuts or pinholes found in the PPE.

Breakthrough time

Manufacturers measure breakthrough time by applying the hazardous chemical to the outer surface of the PPE. Then, they wait until it is detected on the inside surface.

Degradation

When any material is exposed to chemicals constantly, it is bound to degrade. The time these materials take to degrade is measured by the manufacturer. This ensures the consumers are aware of the physical changes to their chemical PPE.

Bottomline

Chemical PPE should maintain its original state for as long as possible. Additionally, they should have low permeation rates.

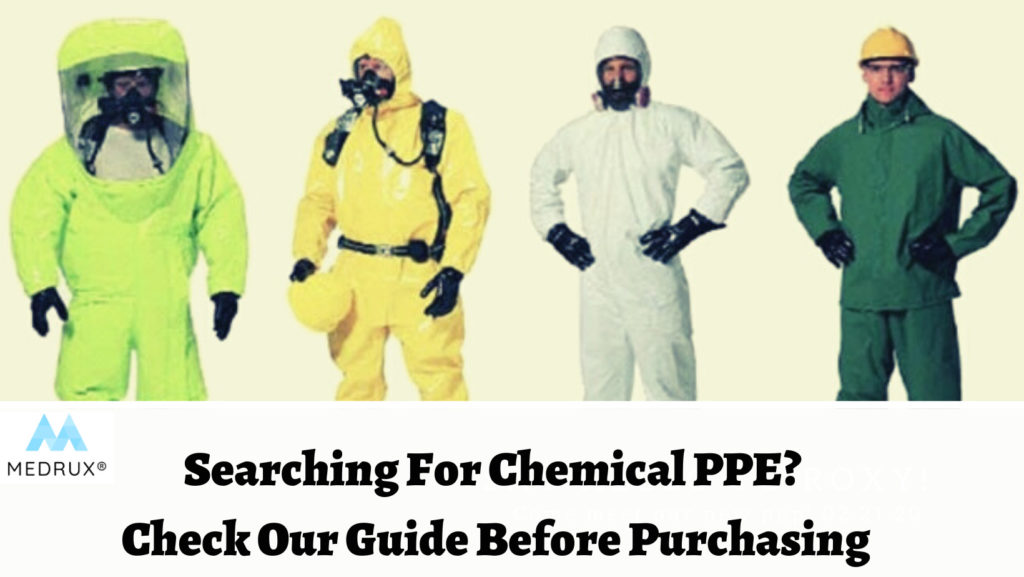

What are the different levels of protection chemical PPE can offer?

There are four levels of PPE stated by OSHA. Each level entails different equipment used by employees in certain circumstances.

Level A

This is the highest level of PPE. This level offers protection against atmospheric hazards and skin exposures. This means that this level requires employees to wear head-to-toe protection.

Therefore, one is required to wear:

- Breathing apparatus like a respirator

- Full encapsulated body suit

- Chemical resistant boots

- Gloves that are layered on the inside and the outside

- A helmet to offer extra protection

Level B

This level offers protection to the respiratory tract. They offer eye and skin protection but are not as thorough as level A. Thus, those working in an environment full of gases and fumes need level B PPE.

The main difference in the equipment used for level B is the suits. Level B suits can be two-piece suits.

Level C

This level pays little to no attention to the face and eyes. It focuses mainly on fighting airborne hazards. Thus, respirators are the main focus of this level.

Therefore, full-face masks have to be worn by the worker.

Level D

This is the lowest level of protection. You can use regular protective equipment for this level. Therefore, respirators are not used for this level.

Bottomline

Only level A PPE can be used as a chemical PPE. This level offers protection for the entire body and your lungs. Therefore, it can protect from spills, splashes, and toxic fumes.

Level B is used for an environment where there are no liquids. Yet, the concentrations of gases constitute a high risk.

Level C PPE is used when the gas levels are manageable. Additionally, there is no danger of your skin or eyes being hurt.

Level D requires only boots and an apron. There is no real danger at this level.

Tips for choosing the suitable material for chemical PPE

Since working with chemicals is a sensitive place to be, you should choose your PPE carefully. Here are some guidelines to aid you in this process.

- Make sure you know the task you need this PPE for.

- Identify all the hazards that you will face.

- Determine the dexterity range you require from your PPE.

- Determine how you will handle the chemicals and for how long.

- Take into consideration the decontamination process you will apply.

- Train your staff on using the chemical PPE correctly and on testing them.

- Consider permeation rate, penetration, and degradation.

Extra tips for handling hazardous chemicals

- Ensure all chemical containers are closed and stored correctly when you are not using them.

- Use trolleys to move chemical flasks. Don’t move them around by holding them in your hands.

- Don’t return the extra chemicals to their original container. This can lead to dangerous chemical reactions.

- Avoid using chemicals that are not labeled.

- Make sure to point the label of the chemicals’ faces upward when pouring them. This will ensure that when pouring chemicals, the labels will stay intact.

- Be careful when working with acids.

Other types of hazards

As previously mentioned, hazards can be due to chemical, thermal, biological, or other hazards. So, allow us to examine some of these hazardous environments up close.

-

Biological hazard

Biohazards are a threat to all living organisms. They include toxins, pathogenic micro-organisms, spores, and medical wastes. Thus, PPE is essential when dealing with any of these materials.

-

Arc hazard

This type is a result of an electric problem. Arcing takes place when an electrical circuit overhears because it’s overloaded. This is very common, and it can result in an arc blast.

Arc blasts or arc flashes can lead to

- Thermal burns

- Hearing loss

- Physical injuries due to shrapnel

- Release of toxic gases

Thus, arc-rated clothing should be worn when dealing with energized conductors or circuits.

-

Physical hazard

This type of hazard is most common on construction sites. Workers are in constant danger of something falling on them or hitting them. Additionally, by-walkers are at risk if they don’t recognize that they are passing a construction site.

Therefore, hi-vis clothing and tape are used to alert the public that construction work is being done in this area.

-

Fire hazard

Fire workers are required to wear flame-resistant clothing for protection. Many things can lead to fire, from forgetting about the stove to handling flammable liquids.

Final thoughts

- Chemical PPE is vital when working with hazardous chemical gases, liquids, solids, fumes, and gases.

- Chemical PPE includes protection for your respiratory tract, face, eyes, hands, feet, and body.

- Protective PPE includes respirators, face shields, goggles, gloves, boots, and body suits.

- Four levels of PPE are available. Level A offers the highest protection and is used to protect from hazardous chemicals. Level D offers the most minor level of protection and includes no specialized safety equipment.

- Make sure you follow the procedure when you handle chemicals.